Recycling program

Download Recycling program - ENG version

Download genbrugsprogram - Dansk version

Introduction

The purpose of the Staermose Industry A/S's recycling program is to establish processes to collect residual materials/waste generated during production, so that these can be recycled. This includes recycling materials such as:

- Cardboard

- Plastic

- Metal scraps

- Wooden pallets

- Other residual materials that can be recycled

Recycling has several significant advantages. In addition to ensuring compliance with applicable legislation, it contributes to:

- Cost savings

- Reducing environmental impact

- Strengthened brand image

- Increased employee engagement

- Competitive advantages, as sustainability is increasingly valued by customers

Collaboration and waste management

Staermose Industry collaborates with certified environmental and waste companies with expertise in modern waste treatment. This ensures proper handling and maximum recycling of our waste.

We use data collection as part of our ESG reporting to get an overview of waste fractions and opportunities for recycling. Waste data is collected on an ongoing basis and reported annually in our ESG reports.

Overview of waste fractions

|

Type of waste |

Faction group |

Form of treatment |

|

Small flammable |

Suitable for incineration |

Combustion |

|

Plastic, cardboard and metal packaging |

Mixed packaging |

Recycling |

|

Corrugated |

Cardboard |

Recycling |

|

Paper mixed |

Paper incl. newspapers |

Recycling |

|

Plastic foil |

Plastic |

Recycling |

|

Food waste (residual waste) |

Organic waste |

Recycling (Biogasification) |

|

Steel and iron - scrap |

Metal |

99.8% recycling |

|

Aluminium - scrap |

Metal |

100% recycling |

|

Pallets |

Tree |

Recycling |

|

Halogen-free cutting oils |

Mineral engine, gear and cutting oil |

Re-refined |

Waste streams

An efficient waste management system contributes to the circular economy, where materials are kept in circulation and waste is considered a resource.

New vs. Recycled materials

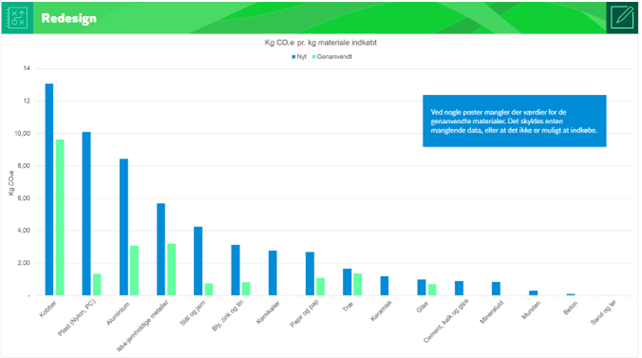

The diagram illustrates the advantages of using recycled materials compared to virgin materials, measured in kilograms of CO₂e per kilogram of material purchased.

Source: The Climate Compass

Advantages of using recycled materials over virgin materials

The use of recycled materials in place of virgin raw materials offers a wide range of economic, environmental, and strategic benefits for both businesses and society as a whole.

Environmental benefits

- Reducing CO₂ emissions: The production of recycled materials generally requires much less energy than the extraction and processing of virgin materials, resulting in lower greenhouse gas emissions.

- Conservation of natural resources: By recycling already extracted materials, limited natural resources such as metals, wood and petroleum products are spared.

- Less waste: Recycling helps to reduce the amount of waste that would otherwise end up in landfill or incineration, reducing the impact on the environment.

Economic benefits

- Cost savings: In many cases, recycled materials are cheaper than virgin materials, especially when the market prices of raw materials are high.

- Supply chain stability: Recycled materials can reduce reliance on global commodity markets and reduce vulnerability to price fluctuations and supply issues.

- Supporting the circular economy: Investing in recycled materials supports a more sustainable and resilient economy, where waste is considered a resource.

Strategic and image benefits

- Strengthened brand and customer trust: Companies that actively choose sustainable materials often experience improved reputation and increased customer loyalty as more consumers prioritize eco-friendly solutions.

- Compliance with requirements and standards: Many industries are experiencing increasing regulatory requirements for documentation of sustainability and carbon footprint – the use of recycled materials is often an important parameter here.

- Innovation and product development: Working with recycled materials can open new design and production methods that ultimately strengthen competitiveness.

Conclusion

At Staermose Industry A/S, we acknowledge our responsibility as a manufacturing company to contribute positively to environmental sustainability. Our recycling programme is not merely a waste management initiative – it is a strategic effort that supports a more sustainable future and fosters a circular economy.

Through targeted sorting, close collaboration with qualified waste management partners and systematic data collection, we ensure that materials are recycled as efficiently and environmentally responsibly as possible. At the same time, we are actively working to increase the proportion of recycled materials in our own supply chain and production processes.

We see recycling not only as a necessity, but also as an opportunity – for innovation, cost efficiency, and enhanced market competitiveness. With a holistic approach, we remain committed to continuously improving our processes and expanding our efforts, ensuring that sustainability remains a core element of our business – for the benefit of customers, employees, and the environment.